Doosan at AGRITECHNICA 2019

This year Doosan is again taking part in the 2019 edition of the AGRITECHNICA fair in Hannover in Germany, the world’s leading fair for agricultural machinery.

At AGRITECHNICA, the world's leading trade fair for agricultural technology, all the leading companies in the industry present their latest innovations. AGRITECHNICA is the showcase of the global agricultural engineering industry and a forum for the future of crop production. Some of the impressive figures at the exhibition include:

- 2,802 exhibitors from 52 countries in 23 halls

- 458,000 visitors from 130 countries / of which 110,000 are international visitors

- A broad, up-to-date forum and conference program

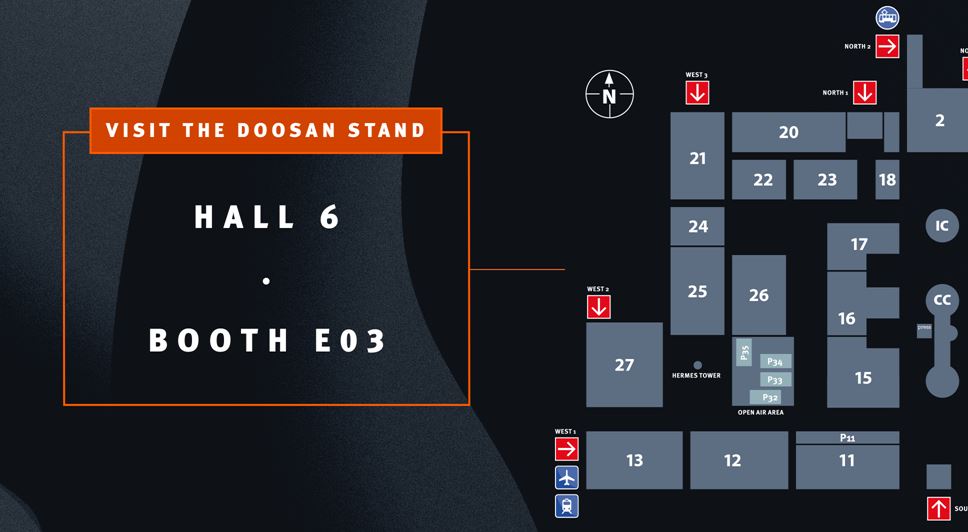

You can find the Doosan Stand here: hall 6, booth number E03

The main machine being displayed: DL280-5 with foldable silage fork.

The highlight of the Doosan stand at Agritechnica 2019 in Hannover, Germany from 10-16 November 2019, is the company’s new DL280-5 wheel loader, designed specifically for agricultural applications.

The DL280-5 is the latest development in the high performance Doosan wheel loader range, which comprises 13 models – covering operating weights from 12 to 36 tonne. The DL280-5 offers high performance and high productivity with unbeatable breakout force, tipping load and enhanced output for all types of work around the farm, including feed management and work on silage and manure clamps. The DL280-5 can be equipped with a variety of attachments such as foldable silage forks and grabs, making it a very versatile and hard working machine for multiple jobs in agriculture.

The DL280-5 is powered by the well-proven 5.9 l Doosan DL06 diesel engine providing 128 kW (172 HP) of power. The engine power is managed via three different working modes: ECO, Normal and Power, to ensure the best torque and power to handle even the toughest work conditions with the best fuel efficiency. As standard, an auto shut-down reduces the idle time of the engine, to prevent the over-consumption of fuel and wasted operating time. Operators can easily set the timing for this function via the LCD display in the cab.

The front lift arm is powered by a closed centre hydraulic system with a 210 l/min axial piston pump. This system provides maximum hydraulic performance, without producing excess capacity, thus saving on fuel and extending the lifetime and reliability of vital components.

High Breakout Force

The DL280-5 features Z-bar kinematics with a simple lifting piston system designed for heavy-duty applications. The breakout force of 145 kN is combined with a constant bucket angle that is maintained throughout the range of movement. Bucket angles are also optimised in the travelling position and at ground level. The lift arm benefits from an automatic Load Isolation System (LIS) – often called ride control – a standard feature which significantly improves the wheel loader’s ride quality and operator comfort by ensuring a smooth ride over rough terrain and reduced cycle times owing to improved vehicle stability when moving.

The DL280-5 has an operating weight of over 15 tonne and is fitted with ZF limited slip axles. Power is sent to the wheels using the ZF automatic Powershift torque converter transmission which has four gears and three driving modes, producing a high output to deliver the highest possible traction force. The gear ratios are optimised and smooth, and shock-free shifts contribute to the high overall level of operator comfort.

The DL280-5 utilizes 750/65 R26 tyres with drive provided by reinforced axles which ensure a high load capacity. The limited slip differential locks at the front and rear automatically ensure maximum traction and easy driving over soft and muddy ground with no need for a manual differential lock. They also reduce the risk of skidding and prevent excessive tyre wear. A hydraulic differential lock – also available – can be activated automatically before one of the tyres starts to slip.

State-of-the-Art Operator Environment

The operator environment is state-of-the-art, with a modern and attractive work space offering generous headroom and full seat movement provides plenty of leg room. An ultra-comfortable Grammer seat is a standard feature with vertical and horizontal suspension, heating and full adjustability.

Of special interest for farm work, the operator has the benefit of additional convex mirrors installed on the lateral mirror frames. The wider angle and additional visibility provided by the convex mirrors along the side of the machine ensure safer manoeuvring of the wheel loader in the yard.

A rear camera provides a clear view of what is happening behind the machine for added safety and peace of mind. The full colour display screen in the cab shows the operator what the camera sees. The panoramic view shows other vehicles coming up behind the loader or people on the ground, and indicators on the screen provide a good perception of distances.

Under Control - Still Online

The DL280-5 has the DoosanCONNECT telematics system as standard – offering customers peace-of-mind by being able to remotely locate, safeguard and monitor operating and production parameters for the machine. On a PC or via a mobile device, a wide range of data can be viewed – fuel consumption, performance, machine use, GPS position, etc. It is also possible to show alarm messages and service intervals. Owners can easily analyse machine operation and plan their work – all of the data is available for their use.